Introduction

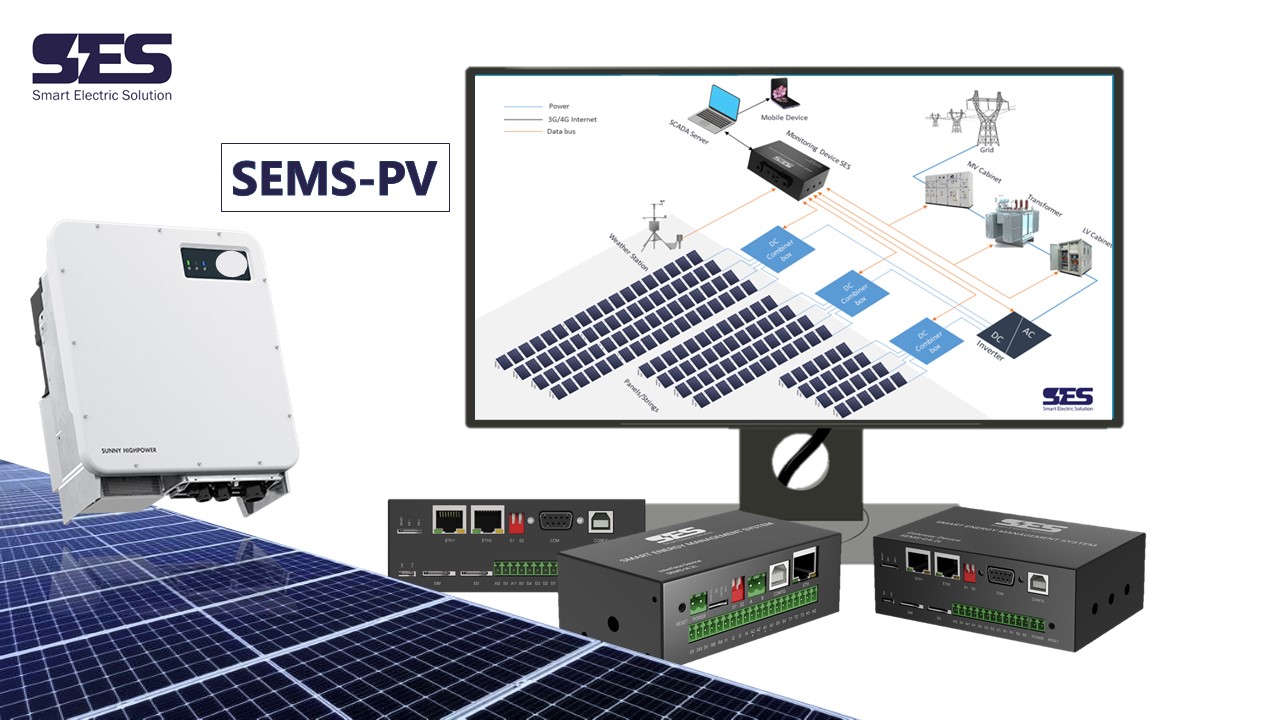

SEMS-PV is a monitoring, diagnosis, forecasting & control solution for solar power systems (Roof-top, power plant scale). It’s an intelligent tool that optimize the management process for solar plant owner, supervisor and technicians.

SEMS-PV towards centralized management of solar power plant, it’s not limited by geographical distance or capability of communication between (different brand of) inverters, … SEMS-PV system is easy to deploy, can be integrated with the existed electrical grid without affecting the existing structure.

I. What is SEMS-PV’s Mission Statement?

1.1. How SEMS-PV works?

The monitoring, diagnosis, forecasting & control functions in SEMS-PV are described as below:

Monitoring

Support the operator to monitor the status of electrical assets in real time.

Warning

Allow user to set upper and lower limit thresholds (for warning parameters) of each device in the electrical system.

Optimizing

Optimize the power generating by solar power plant.

Control

The system can control electrical parameters of the Inverter such as limit the generating power (active, reactive) of the Inverter, support grid stability.

Diagnosis

Maintenance diagnosing & forecasting: The data is collected and processed by Machine Learning, Artificial Intelligence algorithm & paradigm, then the Big Data technology will provide customer the report (of diagnosis & forecasting) that can be used to optimize electrical devices – system.

Forecasting

Machine Learning, Artificial Intelligence algorithm & paradigm will provide forecast, based on the collected data from SEMS-L field devices.

1.2. SEMS-PV aim for:

– OPTIMIZATION of the generating power of solar power plant.

– MONITORING electrical assets in solar power plant.

– FORECASTING total power of solar power plant.

– CONTROLLING the power plant remotely.

– DIAGNOSING the (upcoming) incident, which support operator to make plan for maintenance (CBM).

– WARNING user about abnormal (on the electrical system) in real time.

– Reduce risk of incidents, fire and explosion. Improve safety and reliability.

– Reduce energy losses.

– Reduce labor cost, number of workers.

– Improve the management process: automatically export report, digitalize data; analyze and evaluate performance of each device and the whole system.

– Towards meeting standards, regulations in the electricity industry.

II. The Benefits of investing in SEMS-PV system

In the concentrated operation of many different solar power projects, with many types of solar panels, inverters (components) are in used, the Online- concentrated management will face many difficulties. Most of Inverter manufacturers or construction contractors have solutions for monitoring and controlling the plant (mostly from Inverter manufacturer); however, these solutions are lack of synchronization because of the difference between manufacturers. In addition, the management function according to specific requirements (of customer) is also difficult to meet by the Inverter manufacturer firms. Therefore, SEMS-PV is the most effective solution that can combine different model of inverters, customers are able to change the function according to the specific needs, SESM-PV brings many benefits with reasonable investment costs such as:

Saving

– Saving labor cost (reduce the number of operators in a facility)

– Saving monitoring and inspection time on electrical assets

Optimizing

– Online monitoring electrical assets in real time

– Timely warning of incidents that are occurring in the electrical system

– Sems-PV can integrate with different models of inverters

– Capable of Forecasting the generating power

Flexible reporting system

Customer can export report according to specified needs

Reducing losses

– By diagnosing faults, errors, SEMS-PV can assist the operator to reduce breakdown & repair time

Centralize management

– Customer just need only one account to manage many different PV power plants

User-friendly

– SEMS-PV proudly to be a “made by Vietnam” product that designed to be user-friendly, easy to use

III. SEMS-PV ideal target

Large scale PV power plant

(Capacity > 30 MW)

Sems-PV can be used in energy management for a PV plant or many plants in different areas

Medium scale PV power plant

(Capacity from 1->30MW)

Factories, office buildings, hospitals, other electricity consumption infrastructure, etc.

Rooftop project

(Capacity < 1 MW)

Can be used in energy management for a PV project or many projects in different areas

PV power plants have BESS

(Battery Energy Storage System – BESS)

Factories, office buildings, hospitals, other electricity consumption infrastructure, etc.

Centralize Monitoring & Management for distribution PV power plant

IV. SEMS-PV features

4.1. Monitoring function

Assist the plant operators to follow the states of the PV plant in real time.

Environment parameter

Solar radiation, barometric pressure, environment temperature, wind speed

Panel – String

Monitor panel & string parameters

Combiner Box

Electrical & temperature parameters

Electrical cable

Electric cable monitoring

Inverter

Electrical parameter & device status monitoring

LV cabinet

Electrical parameter & substation device’s status monitoring

Transformer

Electrical parameter & substation device’s status monitoring

MV cabinet

Electrical parameter & substation device’s status monitoring

4.2. Forecasting function

The data is collected from the monitoring system, then processed by Learning machine models and algorithms to make predictions

Generating power

Early forecasting of the generating power (can be forecasted from 1 hour to 3 days)

Performance

Forecasting device & electrical assets performance

4.3. Control function

The Sems-pv system allow user to perform switching, interfere with the electrical assets remotely.

Active power

Control the active power of the PV plant

Reactive power

Control the reactive active power of the PV plant

AC Voltage

Control AC voltage at PCC (Point of common coupling)

Frequency

Control AC frequency to support Electrical grid

Equipment switching

Control the switching device

4.4. Diagnostic function

The data is collected and processed by Machine Learning, Artificial Intelligence algorithm & paradigm, then the Big Data technology will provide customer the report (of diagnosis & forecasting) that can be used to optimize electrical devices – system.

01

Shading problem

02

PV module degradation

03

DC ground fault

04

Dust deposition

05

Abnormal between strings & panels

06

Inverter condition

07

Transformer condition

08

Maintenance plan according to the assets condition (CBM)

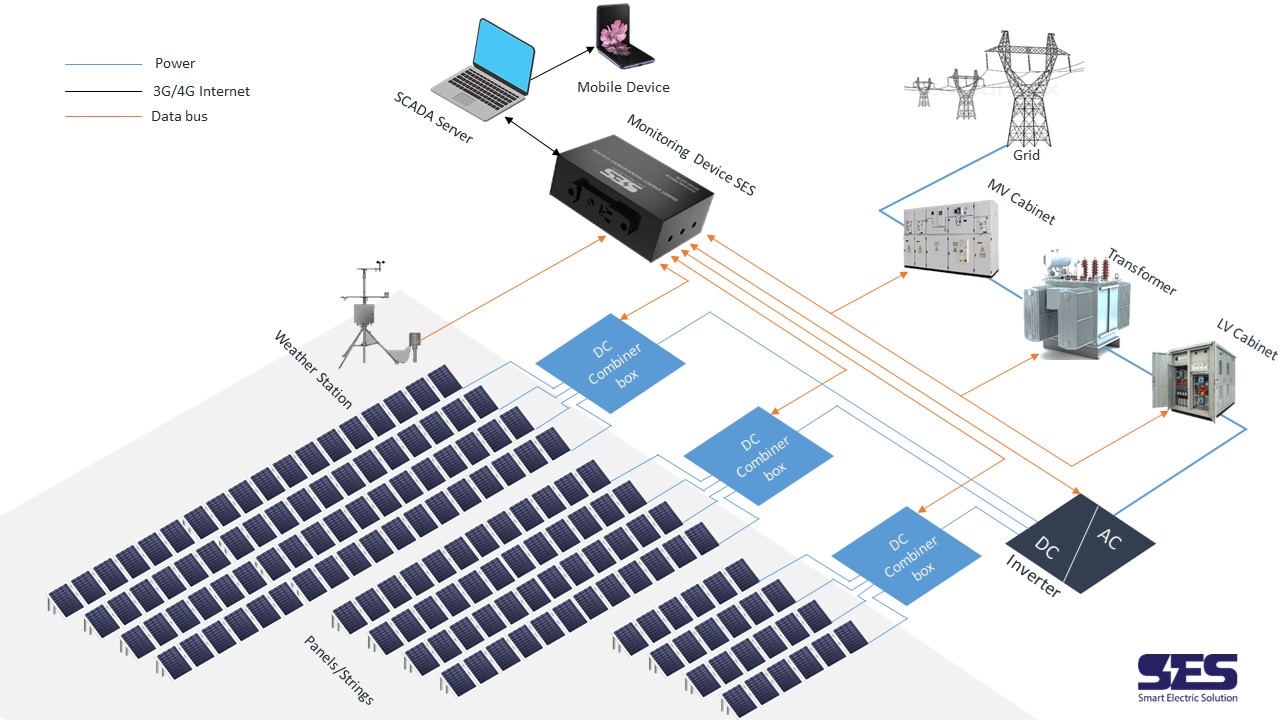

Basically, a PV rooftop, small project or a PV power plant has the same structure, the difference appears if the system has storages or grid-tied. SEMS-PV can connect all the electrical devices and assets to provide a comprehensive management solution for PV power plants (include: monitoring, measurement & controlling). Also, SEMS-PV is capable of centralize management PV projects that are geographically dispersed or have multiple management levels – to meet the requirements of EVN corporation (for monitoring and dispatching).

Solar panel – String Block

A PV panel contain many solar cells, which convert the solar radiation to DC electrical current. Depends on the amount of radiation, the current/ voltage value will be created.

A string is a combination of many solar panels.

Combiner Box

The role of the combiner box is to bring the output of several solar strings together before connecting to a solar inverter.

Solar Inverter

A solar inverter converts DC current to AC current which commonly used in households.

Distribution – tranmission block: Transformer

This block contains: a LV cabinet, a transformer (from LV to MV), a MV cabniet, protection unit, etc. A small capacity PV project (normally) don’t have this block.

The system diagram

I. Data collecting device SEMS-I4.2PV

The purpose of SEMS-I4.2PV is to collect the data from sensors, multimeter, monitoring device, etc.

Specifications

– Installation: Din rail

– Dimension: 108x61x37mm

– Ingress protection: IP40

– Operating temperature: -20 – +60 ºC

– Operating humidity: 0-95%

– Power supply: 24VDC

– Communication: Modbus TCP/IP (Enthernet), Modbus RTU (RS485) CAN/LIN

– Wireless communication: 3G,4G

– Analog input: ✓

– Digital input: ✓

– Digital output: ✓

– Input for temperature sensor: ✓

– Storage: ✓

II. Data processing device SEMS-G4.2PV

Gateway Device: SEMS-G4.2L is a data processing device. The data are processed by Gateway, then transferred to the Server system.

Specifications

– Installation: Din rail

– Dimensions: 130x85x47mm

– Ingress protection: IP40

– Operatong temperature: -20 – +60 ºC

– Operating humidity: 0-95%

– Power supply: 24VDC

– Communication: Modbus TCP/IP (Enthernet), Modbus RTU (RS485) CAN/LIN

– Wireless communication: 3G,4G

– Analog input: Có

– Digital input: Có

– Digital output: Có

– Storage: Có

Catalogue SEMS-PV